Add to Cart

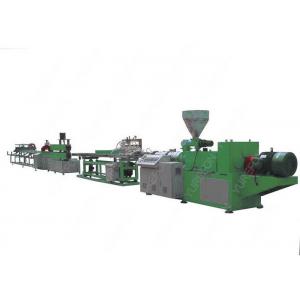

Plastic PVC Cable Trunking Channel Profile Extrusion Making Machine

Product Description

1. Plastic PVC tile trim profile Machine- PVC/WPC tile trim and corner bead Profile Extrusion and Making Machine is applied to produce PVC tile trim profile corner bead profile tile the hollow board like that

2. This production is composed of conical twin-screw extruder, vacuum calibration table, haul-off, cutter and stacker.

3. Chang different extruding mould,this machine can also produce PVC door & window profiles, foamed special shaped materials profiles, decoration plate material, profile and multi-hole wire plastic products, etc.

Technical data

|

|

Max width |

Extruder model |

Motor power |

Max capacity |

|

YF180 |

180mm |

LSZ51/105 |

22kw |

120kg/h |

|

YF240 |

300mm |

LSZ65/132 |

37kw |

260kg/h |

|

YF600 |

600mm |

LSZ80/156 |

55kw |

400kg/h |

|

YF800 |

800mm |

LSZ92/188 |

90/100kw |

650kg/h |

Components of PVC profile production line

a. Conical twin screw extruder:

Using the high efficient conical twin screws, specially designed for PVC power to ensure uniformed plasticization, high extrusion. Stable temperature controlling system can guarantee high quality pipe extrusion.

b. Extrusion Mould:

Spiral type die head will ensure high speed extrusion and avoid the thermal decomposition of amorphous plastics and get high quality PVC profiles. There is heating control system inside of the mould, high efficient, easy to extrude. Bronze calibrators can make the PVC profiles fast calibrated and cooled.

c. Spraying and cooling table:

Rapid vacuum calibrating system allows the hot extruded PVC profiles to be cooled in a very short time and obtain the final size. Automatic temperature control system, pressure regulator, and vacuum control valve greatly enhance the sizing and cooling performance as well as the production speed.

d. Haul off machine:

Adopts caterpillar type suitable for different sizes of pipes. Haul off caterpillar blocks are made of abrasion resistant rubber material, which can make a high and stable hauling speed.

e. Cutting machine:

Precision machine cutter is able to make flat, straight cuts at high speed. A powerful suction device gathers up waste scraps after cutting, thereby making it easier for users to clean the cutter.

Process Flow of PVC panel line:

Raw material +wood power+ additive → mixing → granulating → conical twin-screw extruder → profile extrusion mould → cool molding die → vacuum calibration support → belt haul-off → cutter → rack → finished product inspecting & packing

Raw materials for pvc ceiling panel:

PVC + calcium + other additives.

PVC high chemical stability,panels can be used for a long time.

|

Feeder |

• To feed material into extruder; |

|

Extruder |

•World famous brand electrical component: Siemens,Schneider, ABB etc; |

|

Die head |

• 3Cr13/3Cr17 material |

|

calibration table |

• Include full set of vacuum and water pump |

|

Haul off |

• Upper/lower caterpillar driven separately and speed control by inverter |

|

Cutter |

• Lifting saw cutter with adopts double station dust collection system |

|

Stacker |

• Stainless steel304 as touching material |

|

Hot stamping machine |

• Decorative pattern and film protection of product surface |

Technical information:

|

Parts |

No. |

Name |

Brand |

|

1 Screw and barrel |

1 |

Design |

German design |

|

2 |

Main materials |

38CrMoALA |

|

|

3 |

Screw heating |

Silicon oil heating |

|

|

4 |

Barrel heater |

Cast aluminum heater |

|

|

5 |

Barrel has vacuum exhausting system |

||

|

|

|||

|

2 Driving parts |

1 |

Main motor |

Siemens Brand |

|

|

2 |

Gear box |

Top brand in China |

|

|

|||

|

3 Electric parts |

1 |

Inverter |

ABB brand |

|

2 |

Contactor |

Schneider brand |

|

|

3 |

Relay |

Schneider brand |

|

|

4 |

Breaker |

Delixi brand |

|

|

5 |

Temperature meter |

RKC brand |

|

|

6 |

Hauling motor |

Densen brand |

|

|

7 |

Hauling gear box |

Hard surface gear box |

|

|

8 |

Vacuum pump |

Yvhuang brand |

|

|

9 |

Water pump |

Yvhuang brand |

|

|

10 |

Cutting motor |

Siemens brand |

|

|

11 |

PLC |

Schneider brand |

|

|

|

|||

|

4 Mechanical parts |

We use CNC machines to ensure the precision of our mechanical parts |

||

|

|

|||

|

5 Protection system |

We have a whole set of protection system for our machines, such as: |

||

|

For more technical information please contact us by email. |

|||